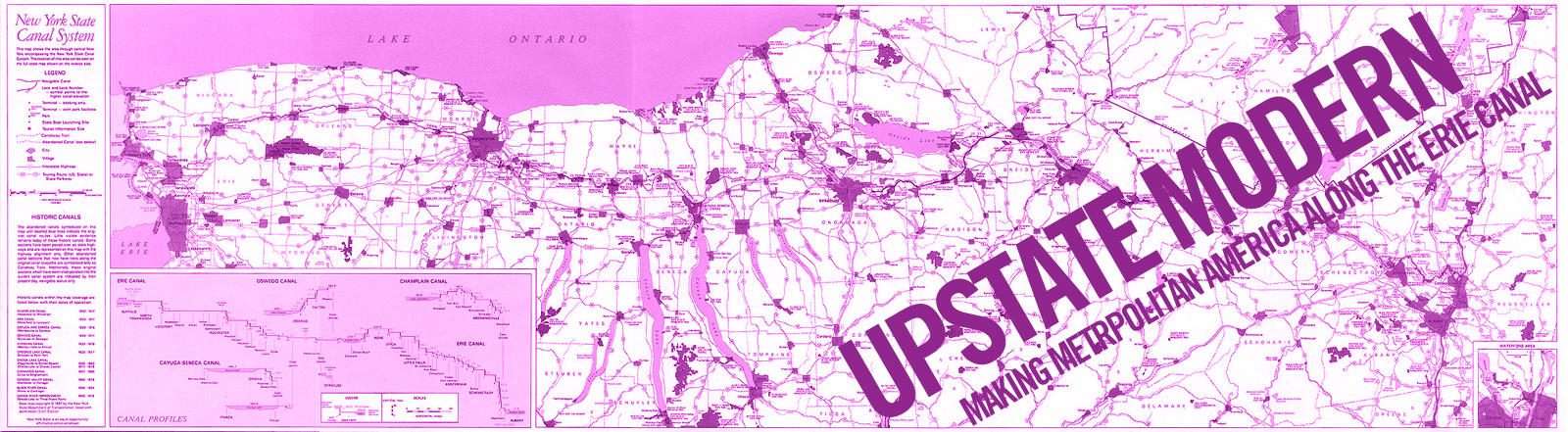

Upstate Modern MAKING METROPOLITAN AMERICA ALONG THE ERIE CANAL

Upstate Modern is a series of courses and public programs at Syracuse University examining the urban history of Upstate New York through transdisciplinary research that draws on archives, buildings, landscapes, and communities.

Confectionery and Cooling

by Shakera Kyle.

During my research I have explored the role of hygrometric materials in industries with humidity sensitive processes and how processed air helped to improve the industry process as well as the conditions of life. The focus of this study has been on the confectioneries industry. While researching I have learned that there are very specific conditioning requirements that vary with each phase of the candy making process. There are various air conditions that need to be taken into account when analyzing a confectionery. These air conditions are organized by a particular part of the manufacturing process, weather it is during the winter or summer months and the temperature and humidity needed that correlates with each season. The list includes processes that are most often named by the room it inhabits such as the Starch Room, Hot Room, Cooling Room, Dipping and Enrobing Room, Packaging Room, Storing Room, Bar Casting Room, Hard Candy/ Cough Drop Spinning and Packing Room. There are also separate processes for chewing gum and sugar storage.

This correlates with my hypothesis that the introduction of air conditioning in the confectionery typology created a series of micro climates that led to improved production methods which spiked product consumption and economic growth. This quote, gathered from the Carrier archives, helps to elaborate on the correlation between economics and its corresponding part the manufacturing process. “It will rarely be necessary to arouse a desire for air conditioning in the mind of the candy manufacturer. It is in his mind but has been represented by fear of the cost. What can be sold is that better conditions can be had at lower operating costs by taking full advantage of outside conditions with properly designed systems. Heat is generated internally in all processes. For summer economy, buildings must be insulated, and this insulation works both ways.” Because heat is generated in all processes, there have been installations of refrigeration which must operate in cold weather months as well as warm weather months. Little was known in the early 1990s of the dollar value of air conditioning to the candy manufacturer, but there was an opportunity for Carrier to sell manufacturers on operating cost.

I plan to visualize this growth of production through means of following various candy products through the phases of is conception and how ;through the addition of modern air conditions; the scale amount of the product affected change. This can be represented by historical comparisons of confectioneries from the early 1990s to the present day. How air conditions aided in the change from hand manufacturing to machine. Also, how these air conditions allowed for extended life of products. Another factor with the addition of these various air conditioning and manufacturing products is the floor plan an how it needs to be taken into account because many of these processes require large instillations that also alter the flow of production.

For image captions and credits, please see the associated spreadsheet.